An increasingly popular operational and strategic imperative, the global eCommerce fulfilment services market was estimated at $140.07 billion in 2025 and is expected to grow at a compound annual growth rate (CAGR) of 14.2% to $272.14 billion by 2030.

With growing importance, it’s necessary to have a strong enough understanding of eCommerce fulfilment to benefit your business, whether you are already working with an outsourced eCommerce order fulfilment specialist or managing fulfilment services in-house.

For any online retailer serious about growth, getting orders out on time and maintaining sufficient stock are key. Delivering your orders quickly and cost-effectively is paramount to profitability and driving repeat business.

Efficient eCommerce fulfilment can provide a significant competitive advantage by enabling faster delivery, reliable service, and operational excellence, helping your business stand out from the competition and boost sales.

In this fulfilment guide, we will explain what eCommerce fulfilment services are, the types of fulfilment available, and the full process that you can expect when you partner with Whistl.

What is eCommerce fulfilment?

Fulfilment in eCommerce is the process of storing, reworking, managing inventory, picking and packing, and distributing fast-moving consumer goods, printed matter, and promotional or business-to-business (B2B) items for sale and resale.

Fulfilment eCommerce services can be facilitated in-house by the retailer or brand, but are often outsourced with a fulfilment specialist due to their space and skills.

What are the benefits of eCommerce fulfilment services?

Outsourcing eCommerce order fulfilment has plenty of service benefits. By partnering with a third-party logistics provider that handles tasks like inventory storage, order processing, packing, and shipping, your business can free up time to focus on core competencies such as product sourcing, product development, marketing, sales, key account management, and customer service. By working in this way, you can streamline your logistics process, whether you need third-party fulfilment services on Amazon, Shopify, or any other platform!

- Enjoy access to economies of scale:

Outsourcing fulfilment can give you access to economies of scale, potentially saving you time and money thanks to lower shipping rates and reduced operational costs by streamlining processes and improving efficiency, while delivering faster order processing. Furthermore, if outsourced, no investment is needed for warehouse space or the workforce to pick and pack orders.

- Reduce risks:

Working with a fulfilment provider with a wide range of carrier partners reduces reliability risk by improving shipping flexibility and providing backup options in case of disruptions. It additionally decreases financial risk by providing access to competitive shipping rates and helps broaden your reach, enabling you to grow into new markets.

- Focus on priorities:

Delegating this responsibility to a third-party specialist will allow you to focus on other aspects of your business and drive growth.

- Enjoy shipping discounts:

Regularly needing high-frequency deliveries makes it easier to negotiate shipping discounts.

- Convenience:

Outsourcing much of the process to trusted professionals can streamline your eCommerce company’s process.

Working with a provider such as Whistl grants you the above benefits, along with the added flexibility to outsource other key elements such as carrier management, mail distribution, advertising, and contact centre operations. Each of these elements can fully integrate to help you deliver the omnichannel experience demanded.

Things to consider when outsourcing eCommerce order fulfilment

Whilst there are several benefits to outsourcing fulfilment services for retailers, you must consider the potential drawbacks before taking further action. For example:

- Branding:

Being dependent on your supplier and the services available through third parties could mean you have fewer opportunities to send out branded products.

- Cost Structures:

Understanding the cost structures of all services available from your chosen supplier/suppliers could impact cost efficiencies. Some may charge separate costs for shipping, warehousing, and staffing to pack and pick orders.

- Dependency:

Outsourcing eCommerce order fulfilment introduces a level of dependency and passing of control that your business may not be used to.

Types of fulfilment in eCommerce

There are several different types of eCommerce fulfilment models and strategies that businesses can adopt to handle order fulfilment in eCommerce, which we will explain in more detail below.

1. In-house Fulfilment

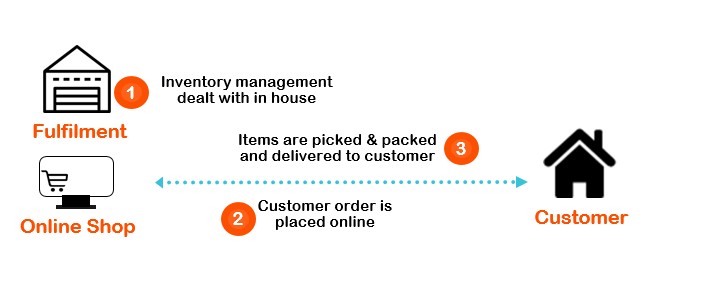

In-house or direct fulfilment is probably the first type of order processing for start-up eCommerce businesses. It involves your company taking control of the entire fulfilment process, from receiving an order to picking, packing, and arranging delivery to customers.

Managing fulfilment internally means your business must handle all the crucial aspects of inventory management, such as storage, ordering, forecasting, and balancing stock levels, to ensure smooth operations and avoid common pitfalls.

This lets your business exercise complete control over its fulfilment process and maintain accountability. Typically, renting a warehouse is necessary to store products and facilitate the processing of orders by pickers and packers.

Benefits of self-fulfilment include:

- Control: Total control means comparing and changing the third parties you work with and implementing the best process.

- Cost-saving: There’s no need to pay third parties for picking and packing, which can appeal to new and small eCommerce firms.

- Customisation: Full control enables the branding of all products sent out.

Considerations:

-

High capital: Paying for a warehouse, maintenance, and extra overheads can become costly. This is in addition to paying more staff to cover the extra jobs self-fulfilment entails.

- Time-consuming: Taking on more jobs yourself could prove more time-consuming for your eCommerce business and restrict growth opportunities.

2. Dropshipping

This type of order fulfilment can be a highly beneficial, hands-off strategy that runs with minimal facilities. The dropshipping process begins when online orders are placed through the ecommerce platform. This is a fulfilment method where the selling merchant doesn’t keep any of the products it sells through its eCommerce site in stock. Instead, it accepts orders and then purchases them from a third party (often a wholesaler or manufacturer) to fulfil them. This means that the selling merchant never sees the goods it sells.

Benefits of dropshipping include:

- Low capital required: You don’t have to invest thousands up front for inventory or pay for overhead to store stock.

- Easy to start: You won’t need to worry about certain factors when starting your business, including paying for products, storage, packing and shipping, and tracking inventory.

- Flexibility: With dropshipping, you can easily be located anywhere in the world and offer a wide selection of products.

-

Considerations:

- Risk: Your third-party partners are responsible for the product supply. This could pose challenges if an item is out of stock after you’ve already accepted an order.

- Cost Structures: Working with multiple suppliers and dropshippers could become complex if you’re not well-organised and don’t have strong supplier relationships.

- Branding: Suppliers will unlikely be willing to add your branding to their products when delivered.

3. Outsourced third-Party eCommerce fulfilment

A combination of dropshipping and self-fulfilment or outsourced fulfilment provides a more balanced option. Working with a 3PL or fulfilment partner gives businesses access to comprehensive fulfilment solutions that streamline inventory management, improve delivery speed, and enable efficient scaling across multiple sales channels. For a growing eCommerce business, it can be highly efficient to reach a wider customer base faster without taking on all the work yourself.

Creating a Strong eCommerce Fulfilment Srategy

Building a robust ecommerce fulfilment strategy isn't just essential; it's what separates thriving businesses from those struggling to keep up in today's digital marketplace. But where do you start? We believe the right strategy begins with choosing the fulfilment model that truly fits your business. Whether you're considering in-house fulfilment, partnering with a third-party logistics provider, or taking a hybrid approach, the choice should reflect your unique needs. Key considerations that really matter include how you'll manage inventory storage, the speed and accuracy of your order processing, and, let's be honest, how shipping costs will impact your bottom line.

What is Whistl’s eCommerce Fulfilment Process?

As part of our eCommerce fulfilment guide, we’ve given a detailed version of our process below. Whistl's fulfilment service covers the entire process, from receiving orders to delivering products to customers. This should help you make an informed decision about whether you think you would benefit from working with us.

1. Onboarding

If you outsource different types of order fulfilment, onboarding is a crucial first step. Your business and the selected outsourced fulfilment specialist should be aligned on your offering, their expertise, and the technical infrastructure of both parties.

Finding a fulfilment house that integrates seamlessly with your eCommerce platform, marketplaces, and order management system will ensure all order and product data is orchestrated accurately. During onboarding, eCommerce fulfilment software can automate inventory management, streamline order processing and integrate your sales channels, making the transition efficient and scalable.

The onboarding stage should include a review with your account manager and integration specialist to map out your current product range, order volumes, and SKUs, and determine how much warehouse space you will need throughout the year, including potential peaks and troughs in demand.

At Whistl, we will also assess whether we can add value to your business and address your specific challenges, such as contact centre support and selecting the right parcel carriers. These additional eCommerce fulfilment services can help companies to exceed their customers’ expectations.

2. Receiving

The first time your products arrive at the warehousing and eCommerce fulfilment facility will be the first ‘receipt of goods’ from your suppliers. To enable local storage and faster delivery, brands need to send inventory to the fulfilment centre, often shipping stock to multiple locations as needed. Once your products arrive, the goods-in team will sign a confirmation note, providing you with documented proof that the team has received your goods, along with the time and inspection details. The goods-in team should also verify the goods receipt against the inventory to ensure that the volumes and products match your orders.

To maximise revenue opportunities, inventory management should be configured to trigger orders with suppliers when stock levels fall below set volumes. If the sales rate exceeds predicted levels, products do not become out of stock or understocked. Well-optimised order fulfilment types and inventory management will ensure maximised sales from managed stock levels.

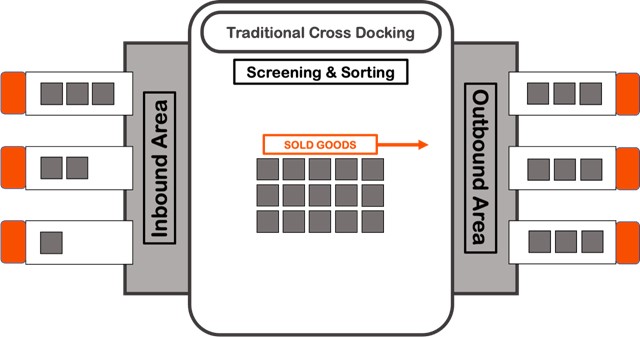

Cross-docking might be required for part-sold or fully sold inventories. The cross-dock process can minimise or remove some of the steps below if the goods are fully sold. For fully sold inventories, cross-dock fulfilment allows for products to be received into the fulfilment centre and dispatched accordingly to the relevant customers or given final destinations.

Learn more about how cross-dock fulfilment works

3. Reworking

Next in our eCommerce fulfilment guide process is reworking. Following the receipt of your goods, the fulfilment house can perform a series of pre-agreed audits and inspections, including checking that:

- Box numbers and pallets match your packing list

- Product volumes match the consignment orders

Inventory management processing can include thorough inspections, for example:

- Checking that the correct number of apparel items is in each box

- Item quality and checks for imperfections or damages

- Checks for variable elements, including sizes and colours, have been supplied in accordance with the order.

Inventory checks should always be coordinated based on the retailer’s unique needs. Many fashion retailers offer personal shopping subscription services, where they take the customer’s clothing and style preferences, along with demographics, and tailor clothing in a monthly or quarterly box. This might require each order to be completely bespoke, with fulfilment teams reworking products into custom arrangements to suit each customer’s specific requirements.

Some retailers may require boxes to be broken down, and items moved into different packaging; in this instance, the reworking can be carried out between the ‘receiving’ and ‘inventory storage’ stages. However, with bespoke fashion retailers, the picking and packing team will typically need to work with the reworking specialists to collect and return items from their stored locations to prepare a customised order.

Request a fulfilment quotation tailored to your order volumes

4. Inventory management

After auditing your products, the received inventory stock is updated in the fulfilment provider’s warehouse management system. Software solutions should integrate easily with the retailer’s order management platform, ensuring complete transparency into the supply chain journey. This would be from the order picking and packing to the final destination via delivery dispatch.

Efficient fulfilment relies on optimised inventory management and real-time data integration, enabling businesses to streamline operations, reduce costs, and improve customer satisfaction.

Delivery to your final location and customers is typically made via UK and international parcel carriers and mailing partners (depending on the customers’ locations and any pre-determined delivery schedule, i.e., transit speed).

Integration with the retailer’s order management platform enables the fulfilment house to analyse the product range and sales data to store products appropriately. This ensures that the fast-selling ‘in-demand’ products are the easiest for the pick-and-pack team to access.

5. Picking

Warehouse picking is an integral part of the eCommerce fulfilment process. At this stage, stored products are collected from their locations to fulfil customer orders. Fulfilment centres and retailers worldwide deploy a wide variety of picking methods. Here are the four most common methods you can expect when you outsource eCommerce order fulfilment:

- Zone picking

The most commonly used method for complex orders that contain multiple items. Products will typically be pre-stored in locations called ‘zones’ to maximise efficiency and ensure picking staff don’t need to travel unnecessarily. Typically, a picking employee will be assigned to their zone.

- Batch picking

This method involves selecting staff who travel long distances throughout the warehouse. If they’re already making that journey, they might as well collect other items in that area while they are there. As such, pickers will typically group orders simultaneously, eliminating the need for multiple trips.

- Discrete picking

The most popular method for smaller warehouses and retailers with a limited number of SKUs (stock-keeping units).

- Wave picking

Similar to discrete picking, wave picking involves picking one order at a time. However, this method introduces scheduling windows to optimise the picking team’s time of day. Wave picking is practical when picking staff are also responsible for packing, reworking, and other areas of the order fulfilment process.

Most modern eCommerce fulfilment houses will use a combination of the above. As the retailer grows in order volumes, their fulfilment provider may evolve from discrete and wave-picking methods to zone and batch-picking to suit the business’s demands. After picking, the next crucial step is shipping orders to customers efficiently, ensuring timely delivery and customer satisfaction.

6. Packing

While your products arrive at the fulfilment warehouse in containers and/or pallets, they are also in boxes, often called ‘outers’ and ‘inners’. However, these boxes aren’t necessarily the packaging that will be used to deliver to your customers. Frequently, the packaging arrives from a separate supplier, or the fulfilment house offers to package it themselves.

Your products may be pre-packed before being selected from inventory or packed according to the packing team's specific criteria. Deciding whether to use generic packaging in the early stages of your business’s growth is essential.

As your business scales, you will likely implement bespoke packaging to enhance your customer experience and reinforce your brand.

Packing isn’t just about putting an item in a box. You may also include surprise gifts to delight your customers, discount vouchers to encourage impulse purchases and return information to ensure your customers have plenty of options available at every stage of their buying journey.

7. Labelling

Once the item is packed, the next step is to print a shipping label from your carrier management system and apply it to the parcel.

If your product is being delivered domestically to somewhere in the UK, this is usually all you need. However, if you are shipping internationally, you must ensure you meet that country's guidelines. For example, suppose you are shipping into the European Union. In that case, you usually will have to include commercial invoices with the shipping label, along with stating your product HS code, your own EORI number and, depending on the item’s insured and actual value, product type and country of manufacture, your customer may be required to pay customs duty to release the item.

8. Shipping

Once your items are labelled and include all the correct documentation, the fulfilment house will group parcels by carrier and destination. Fulfilment centres offer a variety of shipping services to ensure fast delivery for both domestic and international shipping, helping your business meet customer expectations and scale efficiently.

Each parcel will travel along a conveyor belt. Delivery fulfilment specialists will accompany this machine, scanning and sorting each parcel to ensure it is ready when each carrier partner arrives at the fulfilment house to collect it. Global shipping capabilities are essential for reaching customers worldwide and supporting your eCommerce growth.

9. Returns processing

Some studies have found that as many as 30% of products ordered online are returned, compared to less than 9% for brick-and-mortar stores. Therefore, you must work with a fulfilment centre that can help minimise the incidence of returns happening in the first place and manage your returns when they occur. Poor returns management can lead to unhappy customers, resulting in negative reviews and decreased customer satisfaction.

It is essential to ensure that the fulfilment centre's returns process supports revenue growth and facilitates product resale. This might mean working to pre-set product and quality guidelines. For example, for your business, this could mean prioritising products in impeccable condition for immediate resale or refurbishing slightly damaged items before reintroducing them to their respective warehouse locations, known as stock replenishment.

Whistl's Fulfilment Returns Process:

10. Ongoing customer support

We offer ongoing customer support in the last stage of the eCommerce fulfilment guide process. Ongoing customer support is essential for meeting customer expectations and ensuring satisfaction. The customer journey doesn’t end with receiving their goods; our research found that 46% of consumers said they stopped using a company or organisation based on a poor call centre experience. While many fulfilment companies handle only the storage and distribution of products, Whistl also offers eCommerce customer service to complement our fulfilment offering, enabling you to deliver a consistent omnichannel customer experience.

How to Choose an eCommerce Fulfilment Partner

If you’re reading this article, you’re likely already an established retailer. If, like many retailers, you aren’t currently outsourcing fulfilment, it isn’t to be taken lightly. One thing is outsourcing delivery, as most retailers do, but another entirely is outsourcing storage, order processing, stock management, picking, and packing. When choosing a provider, it’s crucial to evaluate the features and benefits of an order fulfilment service to ensure it meets your business needs.

We have found that it is important to demand the following from an order fulfilment provider:

- Suitable locations

When it comes to location, you must check that the order fulfilment provider has strategically located warehouses to slash shipping times and costs. This can help you get orders out on time every time and ensure returns are processed efficiently and cost-effectively.

- Experience or specialisation in your industry

Your brand reputation is at stake, and it’s important that you work with a provider that has experience working with merchants in your product sector and business model.

Remember – every fulfilment company works differently, and many tailor their services to specialist industries. If you have a specific business need, you must source a fulfilment company with a solid track record in handling products and customer bases in your industry. This will enable you to benefit from the partner’s understanding of sector-specific best practices and potential challenges to be aware of.

- Ecommerce Fulfilment Costs

For your ecommerce business, finding ways to reduce fulfilment costs isn't just about numbers; it's about building the right partnerships that help you thrive. When you work with a fulfilment provider, you're not just outsourcing tasks; you're choosing a partner who truly understands your needs. Look for providers who offer transparent pricing (because surprises aren't fun), efficient logistics that actually work, and solutions that grow with you.

- Advanced technological capabilities

Smart inventory practices can be your secret weapon. Just-in-time inventory and dropshipping aren't just buzzwords; they're real solutions that cut storage fees and eliminate the nightmare of overstocking. Automation and AI aren't replacing the human touch; these are techniques that help businesses and fulfilment partners streamline processes. The right fulfilment partner will have a robust technical infrastructure that integrates seamlessly with your sales channels, and an order management system is critical to a time-efficient process. Evaluate the technological capabilities of the fulfilment provider in their ability to integrate with your existing systems. .

- Scalability power

Ensure the fulfilment partner has ample warehouse space to accommodate your current inventory needs and any future requirements. This will give you the opportunity to scale up or down if necessary to align with your business growth and seasonal demands.

- High customer satisfaction rates

You’ll want a partner with high accuracy in order fulfilment, ensuring correct and timely deliveries. This could boost customer satisfaction and loyalty in the long run. Additionally, assess the provider’s efficiency in handling returns and processing refunds to keep consumers happy.

- Flexible approaches

While you may be tempted to just focus on price when it comes to choosing an eCommerce fulfilment provider, you need to consider how the company can work for you. Ideally, you should partner with an adaptable company that puts a laser focus on clients’ continuously evolving needs.

About Whistl Fulfilment

Whistl Fulfilment is one of the UK’s biggest and best providers of integrated multi-channel fulfilment and carrier management solutions. Whistl has extensive experience supporting multi-channel fulfilment. Working with over 50 brands, including Tesco F&F, SharkNinja and Microscooters.

When you partner with Whistl, we help you create those moments that turn browsers into buyers and first-time shoppers into returning, loyal customers. This management process allows you to focus on what lights you up, whether that's crafting amazing products, building your brand, or connecting with your community, while we take care of the behind-the-scenes magic that makes it all work.

Operating from six sites with over 1.5million square feet of multi-user warehouse space, we ship to customers in the UK and internationally at preferential parcel rates, leveraging our scale and proprietary Warehouse Management and Carrier Management platforms to deliver exceptional value.

Whistl's eCommerce fulfilment customer case studies

At Whistl, we have the flexibility to help eCommerce retailers such as Ethical Superstore go one step further by outsourcing not only the fulfilment of their eco-friendly products but also providing dedicated contact centre support.

See how we have helped previous clients with bespoke eCommerce fulfilment services so far:

Thane

As one of the nation’s leading direct-to-consumer businesses, Thane offers the latest home, fitness, and beauty products and was able to enhance its service performance when partnering with Whistl. Whistl provided a seven-day pick-and-pack service with longer processing days, enabling this company to elevate its cut-off times and next-day orders by three hours a day.

The Noble Collection

This licensed manufacturer, distributor, and retailer of television and film properties was able to provide better customer service when collaborating with Whistl. Whistl offered The Noble Collection eCommerce and trade fulfilment as well as contact centre services to deal with huge spikes in order volumes, calls, and emails.

Outsourcing eCommerce order fulfilment FAQs

What is order fulfilment?

Order fulfilment is the procedure of receiving, processing, and delivering consumer orders accurately and efficiently. It can include various tasks like inventory management, order processing, picking, packing, and shipping. The order fulfilment process is critical to eCommerce operations, directly affecting consumer satisfaction and retention.

What is a fulfiment centre?

A fulfilment centre is a warehouse or facility that eCommerce companies and retailers use to store their product inventory, process orders, and fulfil consumer shipments. The centre is where product storage, picking, packing, and shipping occur and can help businesses streamline their operations.

How much do eCommerce order fulfilment services cost?

The cost of our eCommerce order fulfilment services will vary depending on the type of products you want to ship and the size of your business. Storage, packaging, shipping, and returns affect final fulfilment costs.

Watch our video to understand the true cost of fulfilment.

How is third-party logistics different from dropshipping?

While both third-party logistics (3PL) and dropshipping are logistics models used in eCommerce, they differ. In 3PL, the eCommerce organisation owns and stores its product inventory in a third-party warehouse, with the 3PL provider managing order fulfilment and shipping. However, in dropshipping, inventory management is outsourced entirely to suppliers, who ship products directly to consumers.

Should my business outsource eCommerce order fulfilment?

Many companies can benefit from outsourcing eCommerce order fulfilment, although you should consider a few things before doing so. For example, if you want to focus on other parts of your business by freeing up the time you currently spend fulfilling orders, or your audience base is growing, and your infrastructure is struggling to keep up, it might be a good time to outsource eCommerce order fulfilment.

Join our mailing list

Sign up and receive all the latest industry news and insights directly to your inbox.

Research, Insights and Industry Guides

In depth insights and research studies to help you better understand customer perceptions & expectations.

Share this article